PRODUCTS & SERVICES

View All Products & ServicesTHANK YOU FOR YOUR INQUIRY. OUR TEAM WILL BE CONTACTING YOU SHORTLY.

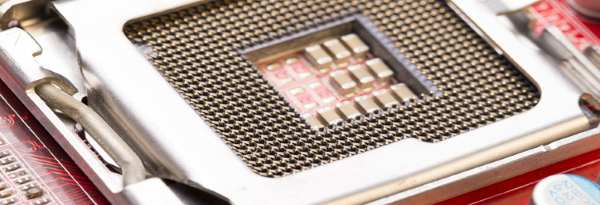

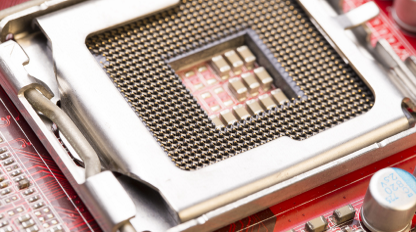

Class II X7R Type Dielectric Powders and Formulations

Ferro is a leading supplier and formulator of Class II X7R dielectric powders designed for use in the manufacture of Class II multilayer ceramic capacitors (MLCC) and single layer capacitors (SLC) as well as for electronic ceramic devices where X7R Class II TCC (temperature coefficient of capacitance) characteristics are required.

We are the preferred source of a wide range of high quality engineered ceramic powders with controlled particle size and chemistry for temperature compensating EIA Class II ultra-stable dielectric materials that exhibit minimal effects on electrical properties with temperature, frequency and time.

Our dielectric materials help MLCC manufacturers meet the demanding dielectric requirements including cost savings, higher performance, and miniaturization needs. Our Class II X7R type formulations deliver excellent dielectric reliability and compatibility with precious metal Silver(Ag), Palladium (Pd), Silver/Palladium(Ag/Pd) and base metal Nickel (Ni) inner layer conductor systems.

Capacitance for X7R varies under the influence of electrical operating conditions such as voltage and frequency. X7R dielectric chip usage covers the broad spectrum of industrial applications where known changes in capacitance due to applied voltages are acceptable.

FERRO CLASS II X7R TYPE FORMULATED DIELECTRIC POWDERS AND MATERIALS

| High Fire X7R Type Dielectric Powders and Materials Our high X7R type dielectric powders are compatible with precious metal conductors and fire in air at peak firing temperatures from 1250°C to 1310°C. |

| Low Fire X7R Type Dielectric Powders and Materials Our Low Fire X7R type dielectric powders and materials are compatible with precious metal conductors and fire in air at peak temperatures from 1080°C to 1140°C. Most of our X7R Dielectric Powders and Materials are processed to be RoHS compliant. |

| Base Metal Electrode (BME) X7R Type Dielectric Powders and Materials Our BME X7R type dielectric powders and materials are compatible with base-metal conductors with peak firing temperatures of 1285°C and 1305°C. All BME X7R type dielectric powders are formulated and processed to be RoHS and REACH compliant. |

X7R TYPE DIELECTRIC APPLICATIONS

- Capacitors

- Filers

- Fuses

- Inductors

- Resistors

- Radio Frequency (RF)

- Microwave Frequency

- Sensors

X7R TYPE DIELECTRIC POWDERS PRODUCT INFORMATION

High Fire X7R Type Dielectric Powders

Low Fire X7R Type Dielectric Powders

Base Metal Electrode (BME) X7R Type Dielectric Powders

VALUE ADDED SERVICES

Ferro takes great pride in our reputation for providing customers with superior technical service and manufacturing support. Our highly skilled technical professionals combine decades of experience with extensive laboratory and technology resources which enables us to provide outstanding customer support and service.

Engineering and Development of Custom Formulations

We help our customers meet the changing needs of the electronic component industry. This includes fulfilling component design needs that simply cannot be met using traditional ceramic dielectric formulations. We work closely with our customers to develop innovative dielectric and conductor material systems that are tailored to meet specific performance targets.

To find out more on our dielectric material development capabilities

Toll Manufacturing and Custom ProcessingOur extensive and flexible manufacturing capabilities help our customers produce high-quality products in varying quantities and formulations. Ferro’s process engineering and operations teams are ready to enable our customers to go to market faster by providing a full range of custom contract manufacturing, joint development programs, and toll processing capabilities.