At the Cutting-Edge of Grinding Technology

Grinding and cutting with Ferro glass and pigments

THANK YOU FOR YOUR INQUIRY. OUR TEAM WILL BE CONTACTING YOU SHORTLY.

Grinding wheels, known in ancient times as milling stones have a long tradition. Today, they come in a wide range of shapes, sizes and compositions for use in all kinds of applications.

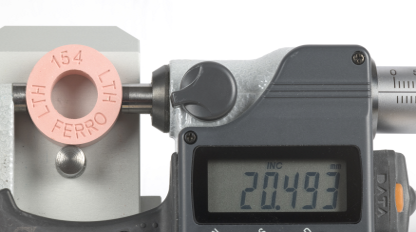

Grinding wheel dimensions vary from 0.5 cm to 1.5 m in diameter, and their velocity in use can reach speeds greater than 120 m/s. And special tests are conducted to guarantee the safety of the grinding wheel during the work process.

Grinding wheels today are highly technical formulations, classified by either the abrasive material or by the type of bond employed. Typical abrasive types are corundum, sol-gel corundum, silicon carbide or the family known as supra-abrasives, comprising CBN (cubic boron nitride) or diamond. Typical bonding classifications are resin, metal or vitreous.

Generally, a grinding wheel needs a bonding system, the abrasive material, and fillers to create porosity. The porosity has two important functions, firstly taking out the abrasive dust, and secondly to bring a cooling agent to the work area.

For modern industrial applications, grinding wheels with a high degree of technical sophistication are required to satisfy performance demands. As such, glass in a bonding system has the advantage of lowering firing temperatures, with better uniformity, better interaction and better coating of the abrasive materials.

The supra-abrasive materials, CBN and diamond, represent different types of materials. Firing temperatures are again limited here. CBN and diamond are inactive materials and require glass with specific attributes to create hard bonds. The glass must achieve a low viscosity at firing temperatures below 900°C. Additionally, a re-softening at 600°C during the grinding process must be avoided. For this, Ferro offers special glasses with a high tendency of crystallization. As a result, with the possibility to use glass in combination with supra-abrasives, the vitreous bonded supra-abrasive grinding wheels have become more and more attractive. And the advantages of longer tool life, precision grinding and feasible speed velocities of >120 m/s have greatly expanded this market.

Ferro’s pigment range can color the wheels in any shade

The trend to lower firing temperatures, combined with a high requirement for bonding strength and high velocity in the grinding process, places very high demands on the glasses. Ferro is tracking these trends and we are constantly working on new solutions to satisfy demand.

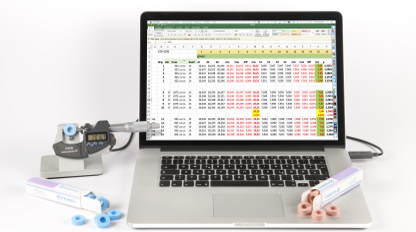

For example, Ferro process temperature control rings, originally developed for critical firing processes for electronic ceramic components, now provide easy and accurate heat measurement for any number of industries – including grinding wheels – in batch and continuous high-temperature processes ranging from 560°C to 1750°C. Their use can significantly improve quality control, for better process temperature accuracy and reliability, at a lower cost.