PRODUCTS & SERVICES

View All Products & ServicesTHANK YOU FOR YOUR INQUIRY. OUR TEAM WILL BE CONTACTING YOU SHORTLY.

Thick Film Materials for Planar Oxygen Sensors

Ferro offers thick-film materials including platinum pastes or inks and high temperature co-firable ceramic tapes for use in planar oxygen sensors.

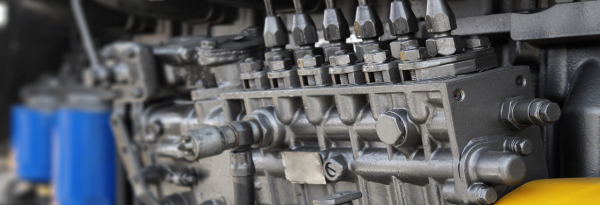

As automotive engine management and on-board diagnostic systems continue to evolve, the oxygen sensors that monitor the air/fuel mixture are also evolving. Modern planar oxygen sensors are now smaller and lower in mass and incorporate a heater within the sensor structure to enable far more rapid response than the heated conical counterpart (seconds as opposed to up to a minute).

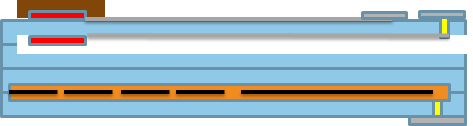

The reference air channel within the sensor requires fugitive materials compatible with HTCC tapes and pastes.

We provide a range of materials that is suitable for the manufacture of the heater/electrode combination found in planar nitrogen oxide (NOx) sensors. The sensitive layer applied to the electrode is normally proprietary, however, Ferro offers paste-making services using customer-specified powders.

EFFECTIVE OXYGEN SENSOR CONSTRUCTION

Multiple layers of HTCC green tapes are implemented, and printed layers are formed using the screen-print technique to produce buried, insulated platinum heaters. All layers are co-fired at peak temperatures around 1550°C, using a correct product mix and prolonged firing regimes to ensure complete burn-out of the thick sensor build and to minimize blistering and warp.

Successful processing and firing of multilayer cofired structures used in oxygen sensors requires knowledge of dimensional stability during layer build and printing, shrinkage during firing, and the necessary firing regime to ensure that flat, blister-free parts are produced.

Ferro has extensive experience in enabling manufacture of these planar oxygen sensors using a combination of tapes and pastes.

Our materials for sensor fabrication include platinum pastes or inks, and high temperature co-firable ceramic tapes. All Ferro materials for use in oxygen sensor fabrication are manufactured to be lead-free, cadmium-free and phthalate-free. All of our HTCC inks and tapes used in planar oxygen sensors are formulated to be RoHs and REACH compliant.

Ferro can also modify existing pastes and tapes to meet specific requirements or manufacture tapes and pastes from customer-supplied powders.

Lot sizes range from a few hundred grams to the high volumes required by the automotive industry.

THICK FILM MATERIALS FOR PLANAR OXYGEN SENSORS

HIGH TEMPERATURE CO-FIRED CERAMIC (HTCC) TAPES AND INK MATERIALS FOR PLANAR OXYGEN SENSORS

| COMPONENT | SENSOR COMPONENT |

FERRO PRODUCT | PRODUCT INFORMATION |

| Porous Overcoat ink | 4569 Porous Zirconia Dielectric Paste | Porous zirconia paste composition used as a protective coating on sensor electrodes | |

| Platinum ink | 5570 Platinum Conductive Paste | Conductive platinum paste used as a gas sensor electrode | |

| Insulation ink | 4530-A Alumina Dielectric Paste | Alumina dielectric paste with high-temperature insulator composition that insulates the platinum heater from the ceramic body | |

| Terminal ink | 5571 Platinum Conductive Paste | Platinum thick film conductive paste used as a terminal pad for external contact | |

| Heater ink |

5574-A Platinum Conductive Paste |

Platinum “resistor” for heater track to heat the sensor to its operating temperature. Typical resistivities are: 20 mOhm/sq for 5571 and 40 mOhm/sq for 5574-A |

|

| Via fill ink | 5575-C Platinum Conductive Via Fill | Platinum via fill conductive paste used to interconnect platinum layers through the zirconia ceramic body | |

| Fugitive tape | 49000-G Fugitive Tape | Fugitive tape used for making cavities in the fired ceramic body | |

| Zirconia tape | 42020-D Zirconia Ceramic Tape | Zirconia tape used as an electrolyte as well as body of the Oxygen sensor | |

| Glue ink | 4431 Dielectric Paste | Glue ink used to facilitate lamination of the different tape layers | |

| Diffusion control | 4494 Porous Dielectric Paste | Used to control the rate of gas diffusion at the electrode surface |

Ferro 42020-D Zirconium Tape for Planar Oxygen Sensors Product Data

Ferro 4431 Dielectric Paste Product Data

Ferro 4494 Dielectric Composition Product Data

Ferro 4530-A Alumina Dielectric Paste for Oxygen Sensors Product Data

Ferro 4569 Zirconia Dielectric Paste for Planar Oxygen Sensors Product Data

Ferro 49000-G Fugitive Tape Product Data

Ferro 5570 Platinum Conductive Paste for Planar Oxygen Sensors Product Data

Ferro 5571 Platinum Conductive Paste for Planar Oxygen Sensors Product Data

Ferro 5574A Platinum Conductive Paste for Planar Oxygen Sensors Product Data

Ferro 5575-C Co-Firing Platinum Via Fill Conductor for Planar Oxygen Sensors Product Data

Ferro has over 20 years of history in designing and manufacturing thick film materials and products formulated specifically for high temperature co-fired ceramics (HTCC) applications.

Successful processing and firing of multilayer co-fired structures utilized in oxygen sensors requires knowledge of dimensional stability during layer build and printing, shrinkage during firing, and the necessary firing regime to ensure that flat, blister-free parts are produced. Our customers can leverage our prototype-building equipment and expertise in these processing aspects.

We also provide training at our own facilities or on-site at our customers’ locations, with comprehensive programs that cover most aspects of sensor manufacturing including materials, equipment, prototype building, testing and evaluation processes.