PRODUCTS & SERVICES

View All Products & ServicesTHANK YOU FOR YOUR INQUIRY. OUR TEAM WILL BE CONTACTING YOU SHORTLY.

CMP SLURRY PRODUCTS FOR SILICON CARBIDE SUBSTRATES

Ferro is a leading global manufacturer of optimized high-purity slurries designed to deliver optimal performance in metal CMP (chemical mechanical planarization) applications.

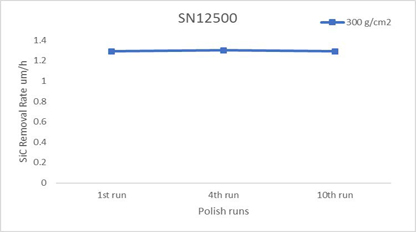

POLISHING PERFORMANCE

- Abrasive: Al2O3

- pH : 8 ~ 10

- 1-kit package (oxidant inside)

- Recyclable

- Suba 800 like pad recommended

- Ra = 0.7 ~ 0.9 Å (AFM)

- No scratch (Laser Tech.)

SN 12001 – FINE POLISH SLURRY FOR SILICON CARBIDE SUBSTRATES

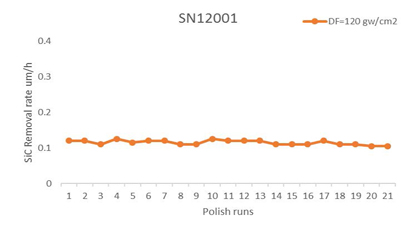

POLISHING PERFORMANCE

- Abrasive: colloidal silica

- pH : 8 ~ 10

- 2-kit package, mix two parts before use

- Oxidant: add oxidant before use

- Recyclable

- Soft polishing pad recommended

- Ra = 0.6 ~ 0.7Å (AFM)

VALUE ADDED SERVICES

With over 40 years of surface finishing experience, Ferro’s research, development and analytical resources enable us to develop unique polishes and abrasives for polishing a variety of substrates including plastic, glass, automotive clear coats, and sapphire.

Our expertise in abrasive particle development and manufacturing technology allows us to optimize the physical and chemical properties needed to deliver optimal solutions for our customers’ varied polishing applications.